Turnstiles are an essential element in modern access control systems. They can be found in airports, office buildings, metro stations, stadiums, and industrial facilities

Their role is to manage the flow of people smoothly and securely, while preventing unauthorized entry.

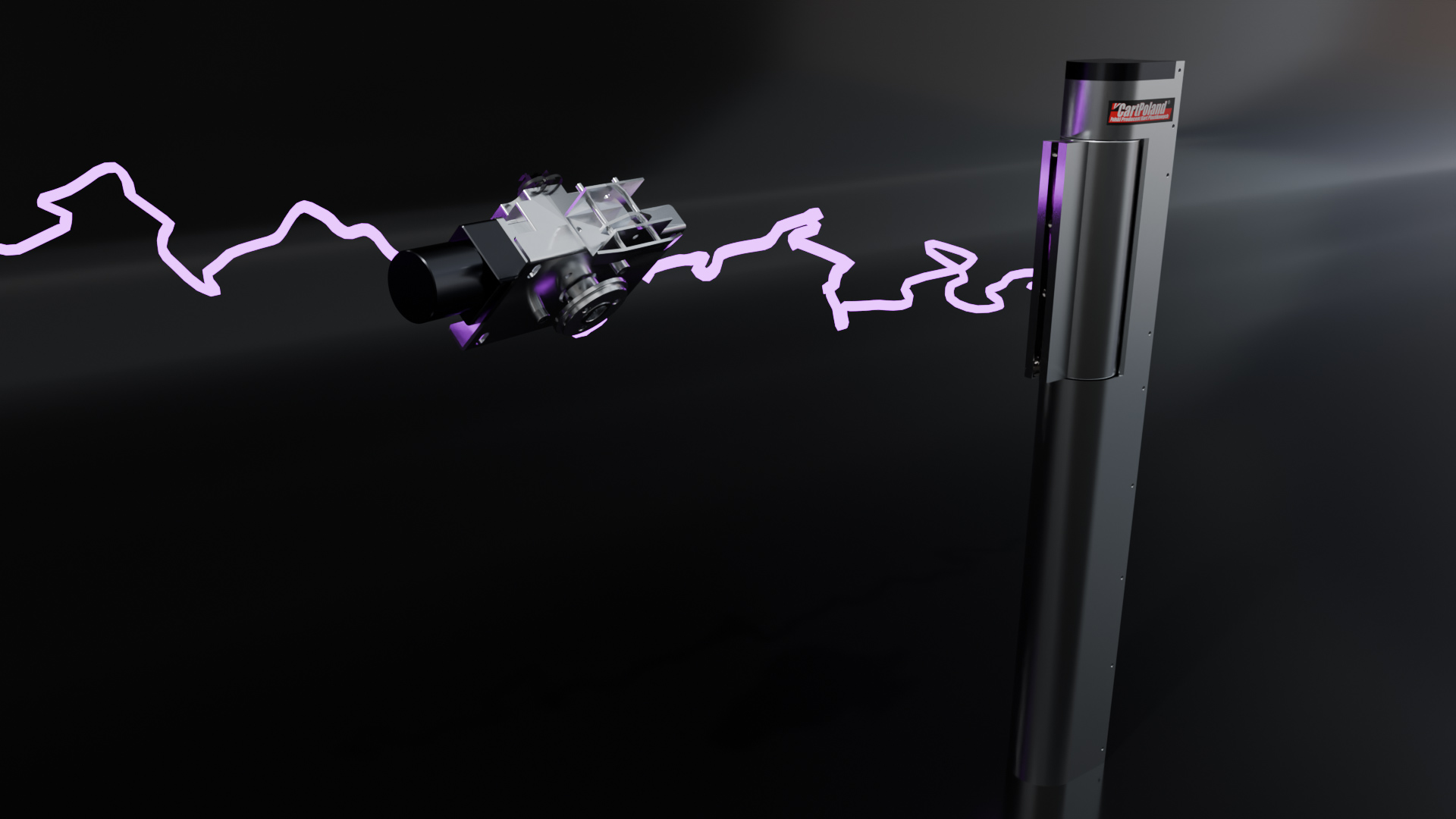

At the heart of every turnstile lies its drive mechanism, and increasingly, BLDC motors (Brushless Direct Current) are becoming the preferred choice over traditional brushed DC motors or electromagnetic drives.

What Is a BLDC Motor?

A BLDC motor is a brushless direct current motor, designed to operate without the mechanical commutation found in traditional DC motors. Instead of brushes and a commutator, it uses electronic commutation controlled by a dedicated driver.

The rotor contains permanent magnets, while the stator has windings that are energized in a precise sequence. Hall sensors or sensorless control algorithms detect the rotor position, allowing the controller to adjust torque and speed with high accuracy.

Why BLDC Motors Are Ideal for Turnstiles

A turnstile motor needs to:

- react instantly to access control signals,

- operate smoothly with no jerks or sudden stops,

- withstand hundreds of thousands of operating cycles per year,

- work quietly, especially in offices and public spaces.

- BLDC motors excel in all of these areas. Electronic commutation significantly

- reduces friction and mechanical wear, leading to longer service life. The motor

- controller can dynamically adjust torque for different scenarios, such as

- emergency operation or slow, controlled movement for enhanced safety.

Key Advantages of BLDC Motors in Turnstile Applications

- Long Service Life – no brushes means no sparking and reduced heat generation, resulting in minimal wear.

- Smooth and Precise Movement – the motor responds accurately to control signals, ensuring a comfortable user experience.

- Low Noise – essential in high-traffic areas where noise reduction matters.

- Energy Efficiency – higher electrical efficiency compared to brushed motors.

- User Safety – features like “free rotation” mode for emergency evacuation.

- Flexible Control – seamless integration with access control systems, from RFID cards to facial recognition.

BLDC Motor Operation in a Turnstile

In a typical tripod turnstile equipped with a BLDC motor, the process works as follows:

- The user presents a valid access credential, such as a card, QR code, or ticket.

- The access control system sends a signal to the motor controller.

- Based on rotor position feedback, the BLDC driver applies precise torque.

- The turnstile arm rotates smoothly by 90° or 120°, allowing one person to pass.

- The mechanism returns to its locked position, ready for the next cycle.

BLDC Mechanisms by CartPoland

CartPoland has years of experience in designing and manufacturing BLDC-driven turnstile mechanisms that combine cutting-edge technology with industrial-grade durability.

Our solutions are engineered to perform reliably in high-traffic environments, from busy public transportation hubs to corporate headquarters and secure industrial sites.

CartPoland BLDC mechanisms offer:

- extended lifespan with minimal maintenance,

- smooth and quiet operation,

- compatibility with any access control system,

- robust safety features for user protection.

- This makes our turnstile drives a trusted choice for both domestic and international clients.

Conclusion

BLDC motors represent the most advanced technology available for modern turnstiles. They deliver unmatched reliability, safety, energy efficiency, and operational smoothness.

As demands for secure and efficient access control continue to grow, BLDC technology is becoming the industry standard.

By choosing CartPoland BLDC turnstile mechanisms, you invest in long-term performance and peace of mind.